1 / 3

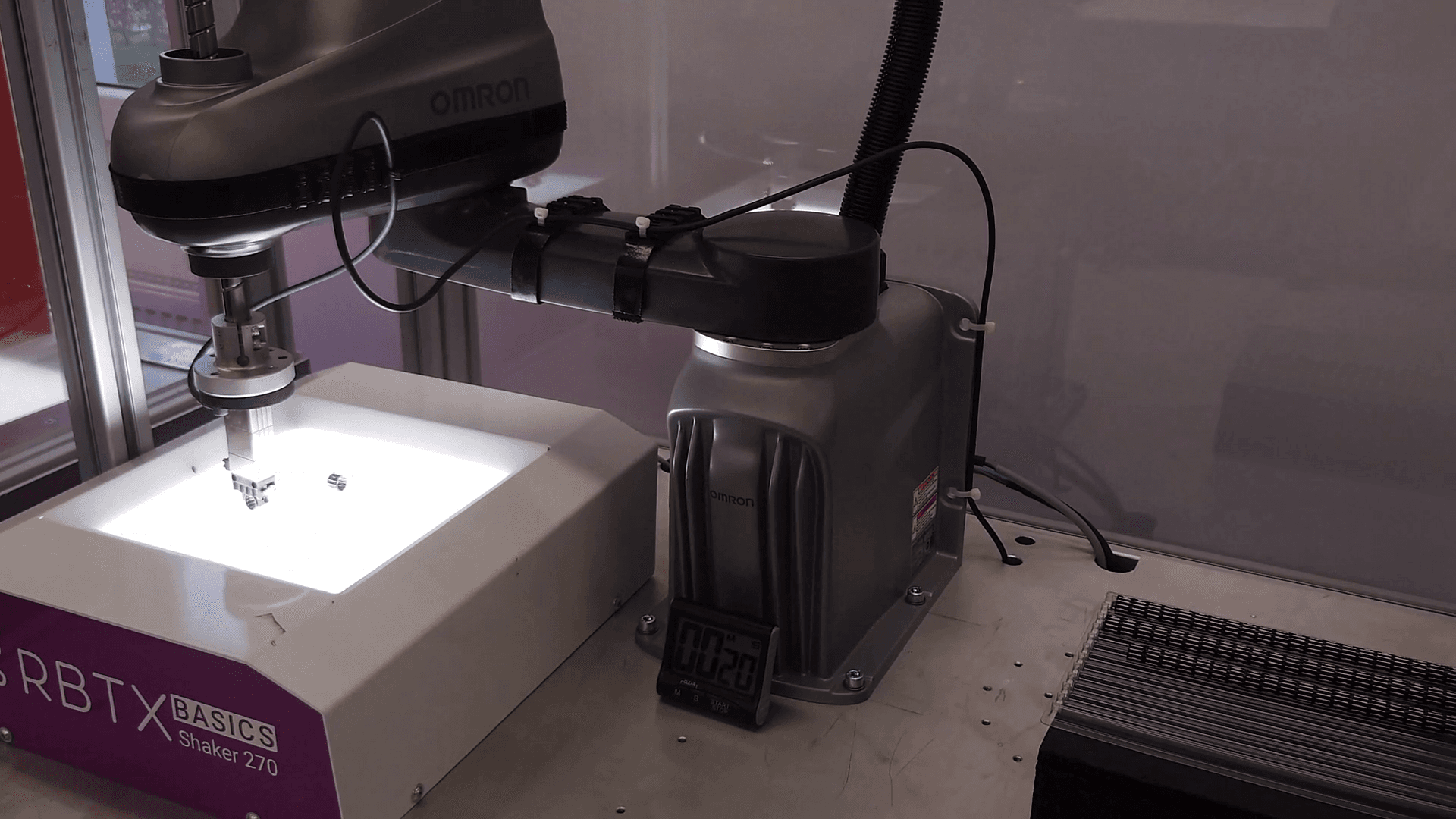

1 / 3Conveyor belt picking with 2 Delta robots

Hardware Price:

Build

DIY

Characteristic

Lubricant-free

construction

compact

In this application, 2 Delta robots were positioned at the end of a Kitz assembly line. The first Delta robot places the components on the conveyor belt, while the second robot then removes and sorts them. The setup illustrates how partial automation with 2 robots in combination with an assembly line can be easily implemented.

The igus® Delta robot is available as a 2-axis robot with 400 or 700 mm as well as with 3 axes and a working space of 360 or 660 mm. Delta robots are ideal for fast pick and place tasks and can be programmed easily and without special prior knowledge with the igus Robot Control.

3 Components