1 / 3

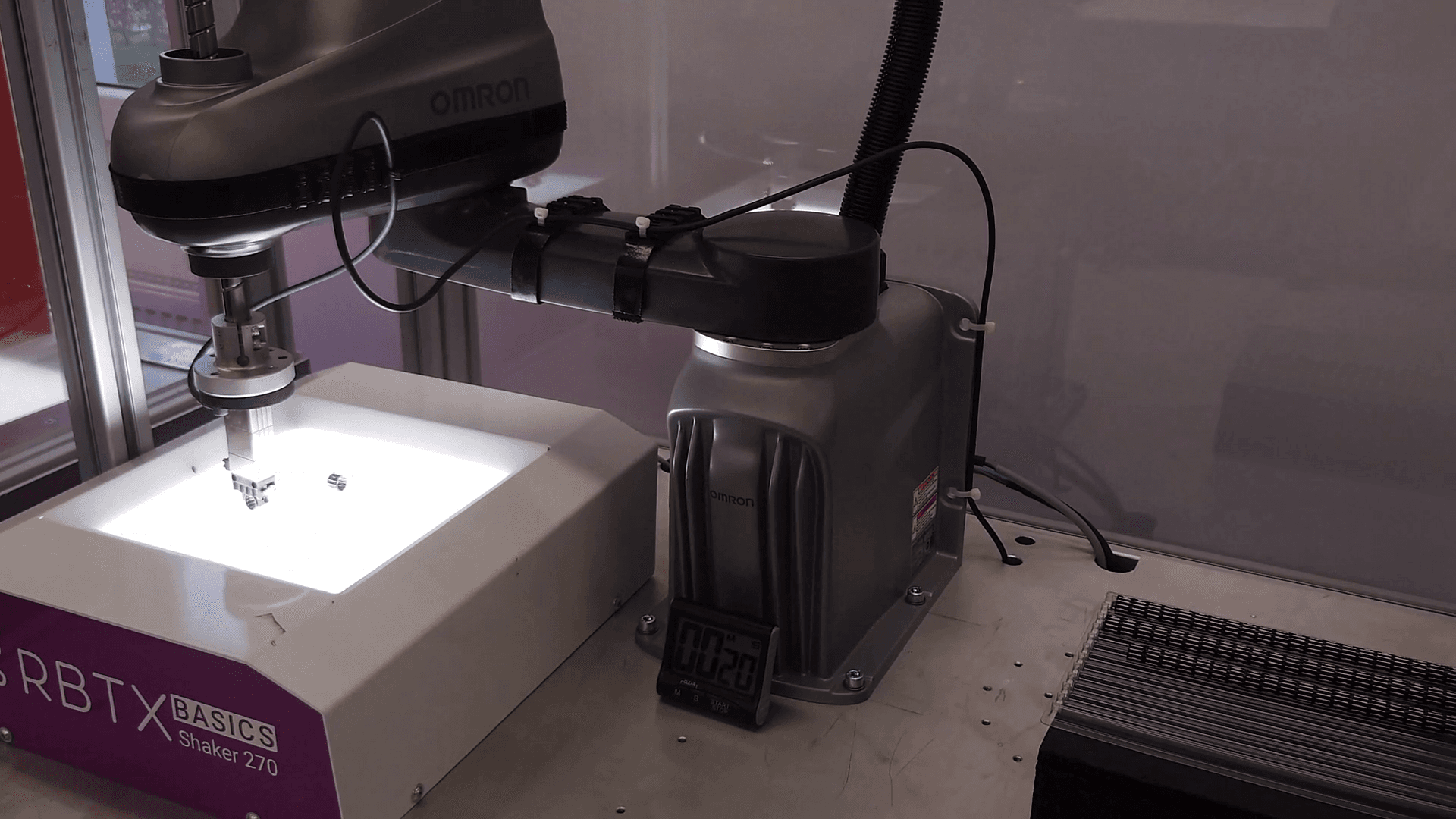

1 / 3Automated screwdriving application - cycle time test

Hardware Price:

DOF

3

Working space

800x800x500

mm

ROI

< 12

months

Precise Screw Handling with igus Gantry and Kolver Screw Gripper

The automation of precise screw handling is critical for maintaining high productivity and accuracy in assembly processes. This solution integrates an igus gantry system with a Kolver screw gripper, combining accurate three-dimensional movements with precise screw manipulation. During testing, the setup demonstrated efficient and coordinated performance, highlighting its ability to meet strict cycle time requirements.

What is the Application?

The system automates screw gripping, turning, and positioning tasks. The igus gantry moves the Kolver gripper to predetermined positions, enabling screws to be handled, turned, and placed with high precision.

What are the Advantages of the Solution?

High Precision: Ensures accurate placement and manipulation of screws.

Cycle Time Compliance: Performs full task cycles efficiently and consistently.

Reliable Performance: Reduces errors while maintaining operational speed.

What are the Advantages of the Robot?

The combined use of the igus gantry and Kolver screw gripper offers:

Flexibility: Supports multi-directional movements for varied tasks.

Robust Design: Handles repetitive operations with minimal downtime.

Ease of Integration: Compact design fits seamlessly into assembly lines.

Boosting Assembly Efficiency with Precise Automation

The integration of the igus gantry and Kolver screw gripper provides an innovative solution for screw-handling tasks, combining speed, accuracy, and reliability. Through its adherence to cycle time requirements, this system offers manufacturers a scalable and efficient way to enhance operational workflows and maintain precision in demanding production environments.

2 Components