1 / 3

1 / 3Pick and Place laser box

Hardware Price:

DOF

5

Repeatability

1

mm

Max. speed

0.2

meters per second

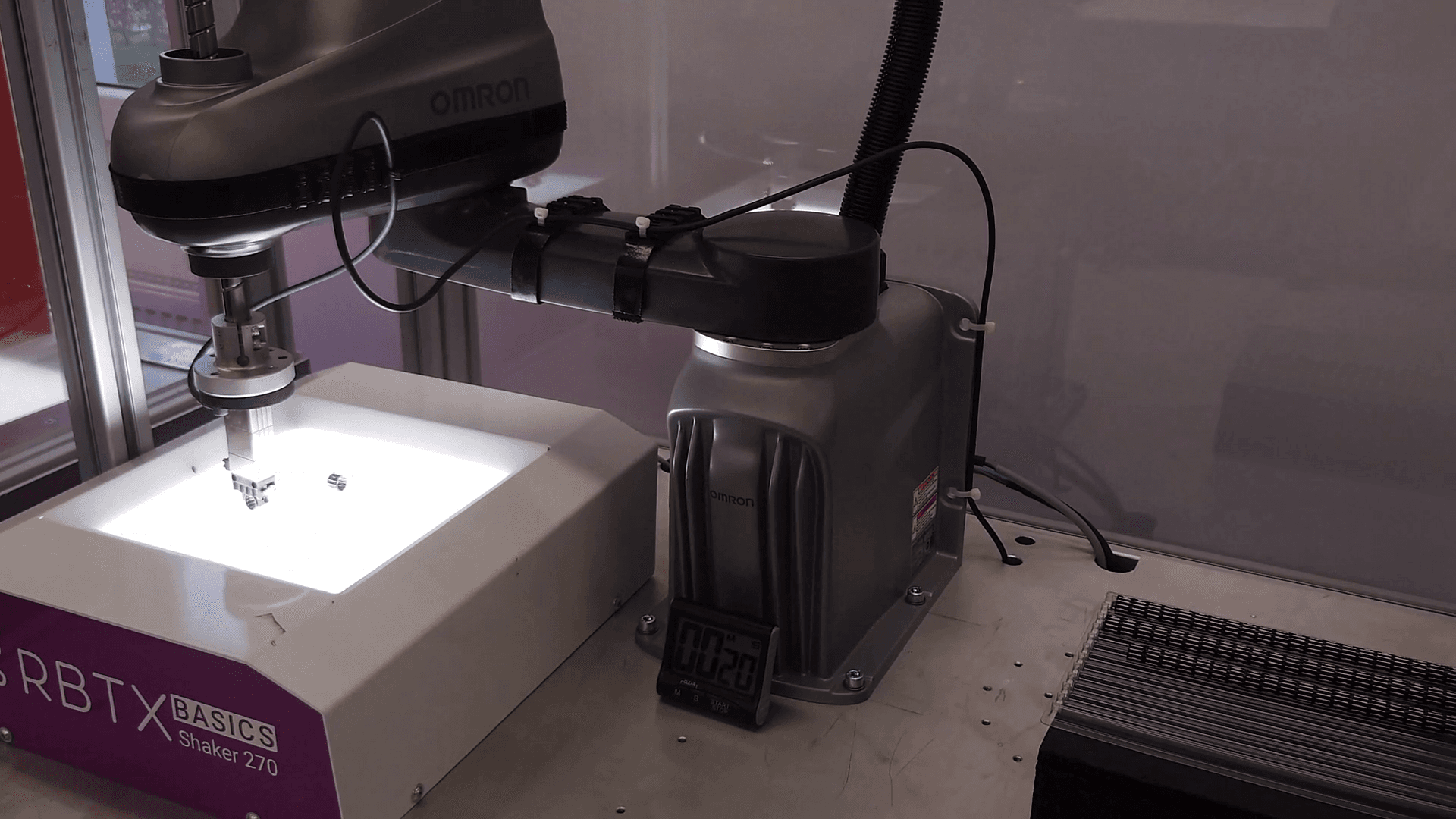

Automating Pick-and-Place with Articulated Arm Robot: Precision in Laser Scanning

In this customer test, an articulated arm robot was employed to automate a classic pick-and-place task. The objective was to transfer thin components, such as a pen, into a laser box for scanning, and then remove them after the process. To handle the delicate pen, the robot was equipped with a small, precise end effector. With a 5-axis design, a reach of 790 mm, and a payload capacity of up to 3 kg, this jointed-arm robot delivers reliable performance for repetitive handling tasks. Options for mounting on an additional drylin axis further expand its workspace adaptability.

What is the Application?

The robot automates pick-and-place operations for scanning components, making it ideal for applications requiring precise handling in industries such as electronics or quality control.

What are the Advantages of the Solution?

High Precision: Accurate placement ensures reliable scanning results.

Versatile Design: Adapts to workspace needs with optional drylin axis.

Enhanced Workflow: Reduces manual labor, increasing overall efficiency.

What are the Advantages of the Robot?

The articulated arm robot offers robust performance in automated tasks:

Compact and Flexible: Reaches components even in constrained spaces.

Reliable Payload Handling: Supports up to 3 kg, suitable for diverse items.

Customizable Integration: Easily equipped with specialized end effectors.

Streamlining Laser Scanning with Robotic Automation

This articulated-arm robot solution simplifies repetitive laser scanning workflows, delivering precision, flexibility, and efficiency. By automating the handling process, businesses can reduce labor costs, improve consistency, and optimize production processes with reliable robotic technology.

2 Components