1 / 3

1 / 3KBL Brushless Screwdriver Integration

Hardware Price:

DOF

3

Build

DIY

Operation

Maintenance-Free

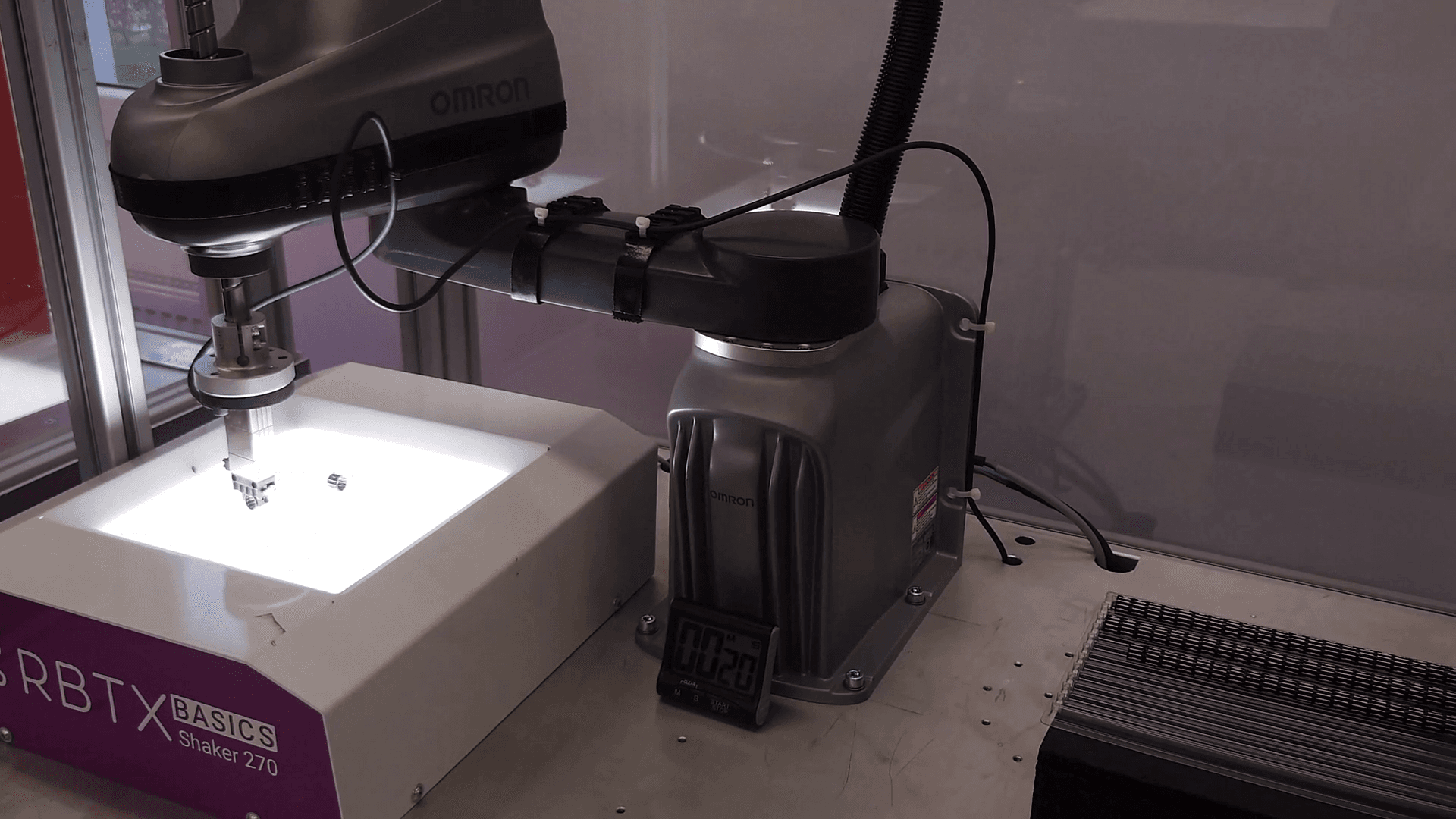

Enhancing Assembly Efficiency with KBL Brushless Screwdrivers and igus Robots

Integrating Kolver's KBL Brushless Screwdrivers with igus gantry, delta, and Rebel robots offers an innovative solution for precise and efficient screw tightening in clean room applications. These state-of-the-art screwdrivers utilize brushless motors, delivering high accuracy and reliability while eliminating maintenance requirements. Combined with igus automation systems, the setup optimizes assembly processes to meet modern manufacturing demands.

What is the Application?

The system automates consistent and accurate screw tightening, ensuring reliable torque control in environments where precision and cleanliness are critical.

What are the Advantages of the Solution?

Maintenance-Free: Brushless motors eliminate wear and reduce downtime.

Improved Accuracy: External torque adjustment and electronic control minimize errors.

Clean Solution: Perfect for clean-room applications with zero pollutant emissions.

Cost Optimization: Affordable yet effective, reducing operational costs.

What are the Advantages of the Robots?

Using igus gantry, delta, and Rebel robots delivers:

High Precision: Ensures repeatable screw tightening without variability.

Flexible Integration: Adapts seamlessly to assembly workflows.

Durability: Robust design ensures consistent performance over time.

Revolutionizing Assembly with Integrated Tools

Combining Kolver KBL Brushless Screwdrivers with igus robotic solutions provides unparalleled efficiency in screw tightening operations. This integration not only enhances precision and reliability but also offers cost-effective and clean solutions for modern manufacturing, ensuring optimized assembly workflows.

1 Component