1 / 3

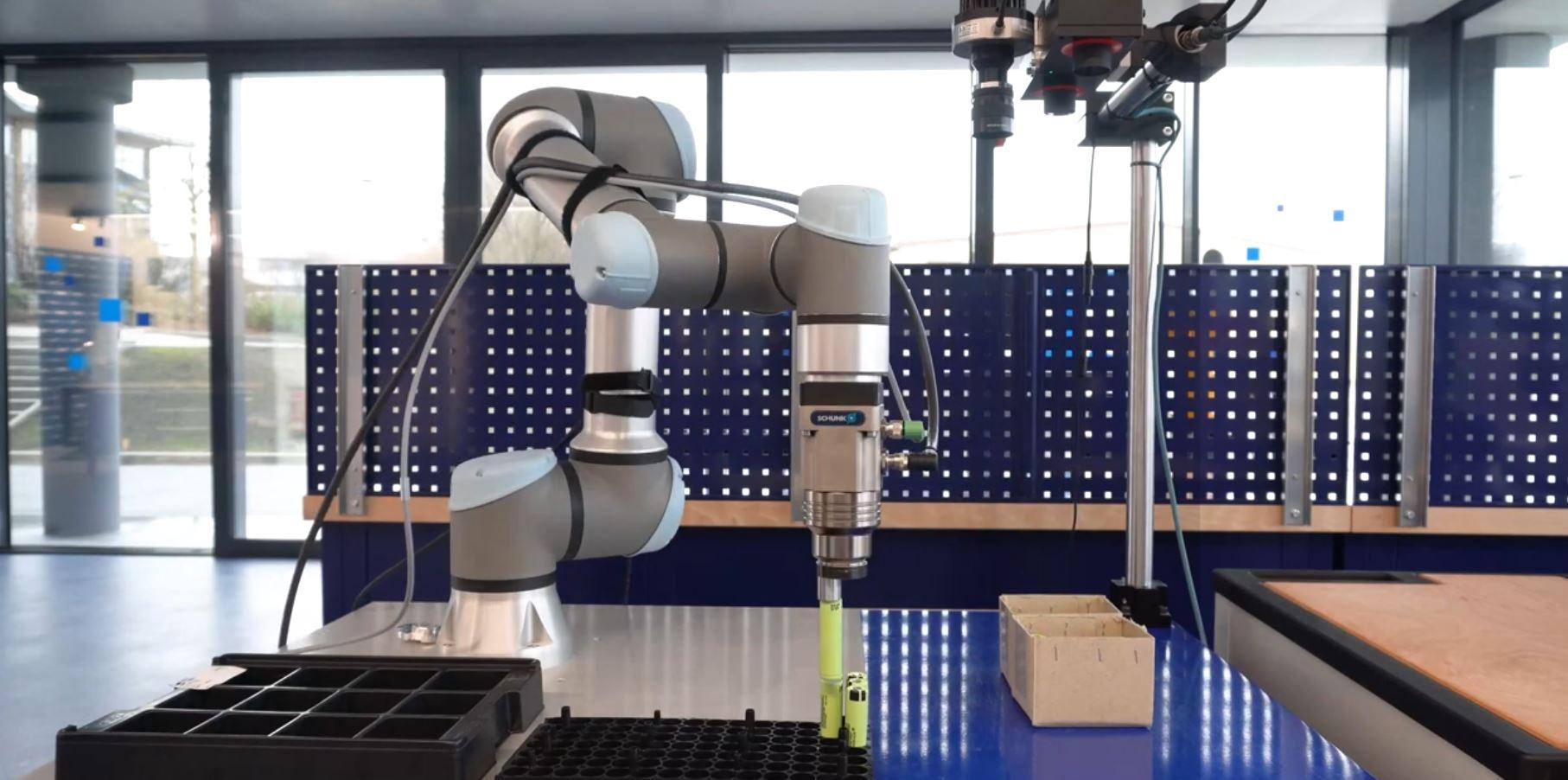

1 / 3Separate screws using rotary feeder and robot

Hardware Price:

Runtime

24h

DOF

4

Repeatability

0.5

mm

Efficient Screw Handling with FlexiBowl System: Precision and Productivity

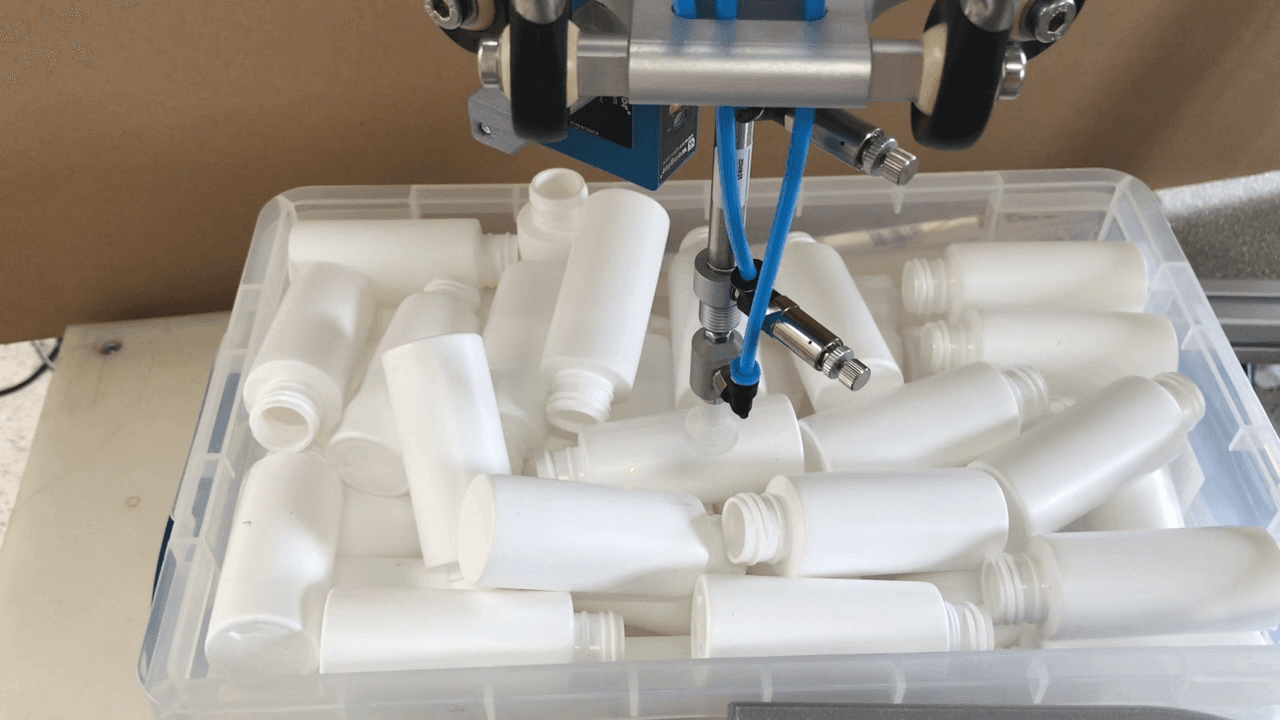

Screw separation is an essential step in industrial assembly, requiring speed and precision to optimize workflows. The FlexiBowl system provides an innovative solution for automating screw separation, ensuring efficient handling and precise delivery for further processing. With its advanced technology, the system handles high quantities of screws quickly and accurately, boosting productivity and reducing manual workload.

What is the Application?

The FlexiBowl system automates screw separation, picking up and individually sorting screws before making them available for subsequent assembly processes. Ideal for diverse industrial applications, it supports efficient screw handling in high-demand environments.

What are the Advantages of the Solution?

Improved Efficiency: Processes a large number of screws in minimal time.

Enhanced Accuracy: Ensures precise separation, reducing assembly errors.

Versatility: Compatible with various screw types and assembly setups.

What are the Advantages of the Robot?

The FlexiBowl system excels in delivering reliable automation:

High Speed: Handles high quantities without compromising precision.

Flexibility: Adapts easily to different industrial applications and screw types.

Compact Design: Fits seamlessly into existing assembly lines.

Boosting Assembly Line Performance with FlexiBowl

The FlexiBowl system revolutionizes screw handling processes by enhancing efficiency, accuracy, and overall productivity. By automating screw separation, industrial companies can significantly improve assembly line performance, ensuring smoother workflows and increased output in competitive environments.

4 Components