1 / 3

1 / 3Automated packaging with igus Gantry

Test before Invest

Hardware Price:

DOF

3

Repeatability

0.5

mm

Max. payload

10

kg

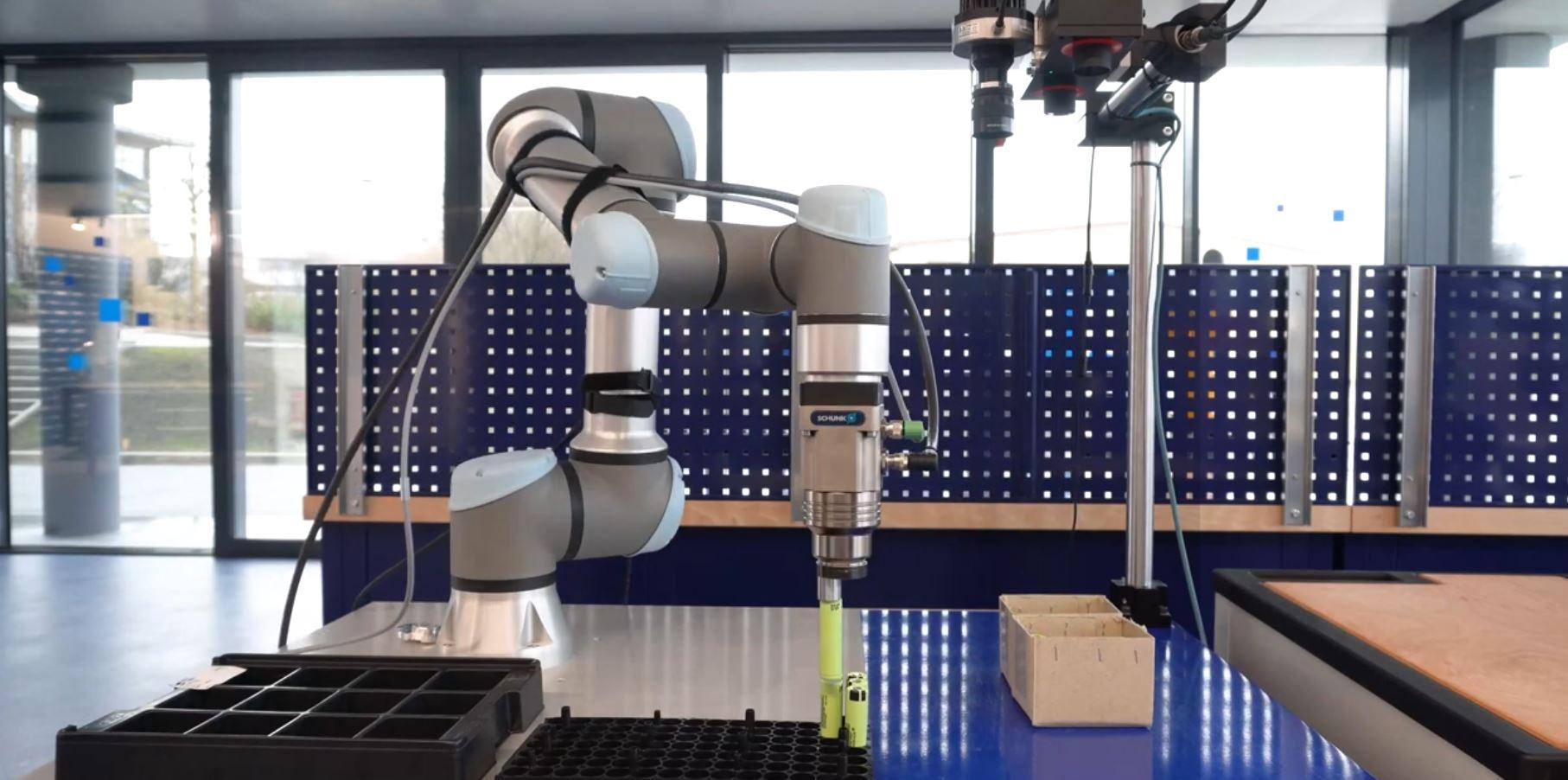

igus Gantry System with Pneumatic Suction Gripper: Precision and Efficiency in Packaging Automation

The video introduces the igus gantry system in the Customer Testing Area, equipped with a pneumatic suction gripper for pick-and-place tasks. This advanced system is designed to precisely move objects in a three-dimensional space. In this application, the gantry system efficiently handles cartons (packaging materials), demonstrating its reliability in industrial environments. The suction gripper ensures safe manipulation of packaging, seamlessly picking up cartons, moving them, and placing them at designated locations with accuracy and speed.

What is the Application?

The system automates carton handling, streamlining packaging workflows and reducing manual labor in industries such as logistics and manufacturing.

What are the Advantages of the Solution?

Improved Efficiency: Accelerates pick-and-place tasks, saving time.

Reliable Precision: Ensures accurate positioning of cartons.

Versatile Design: Adapts to various packaging sizes and materials.

What are the Advantages of the Robot?

The igus gantry system with suction gripper delivers:

Seamless Operation: Pneumatic gripping ensures secure handling of cartons.

Durable Components: Built for consistent performance in demanding environments.

Customizable Setup: Easily adaptable to different industrial applications.

Streamlining Packaging Processes with igus Gantry Technology

The igus gantry system paired with a pneumatic suction gripper exemplifies how advanced automation can optimize material handling tasks. By ensuring precision, reliability, and efficiency, this solution is ideal for industries looking to enhance productivity while minimizing costs and reducing manual intervention.

3 Components